Welcome to a showcase of my patented creations—born from a relentless passion for solving complex challenges and bringing new ideas to life. Each invention tells a story of curiosity, creativity, and a drive to transform possibilities into reality. Dive into the world of innovation and explore how these breakthroughs contribute to advancing technology.

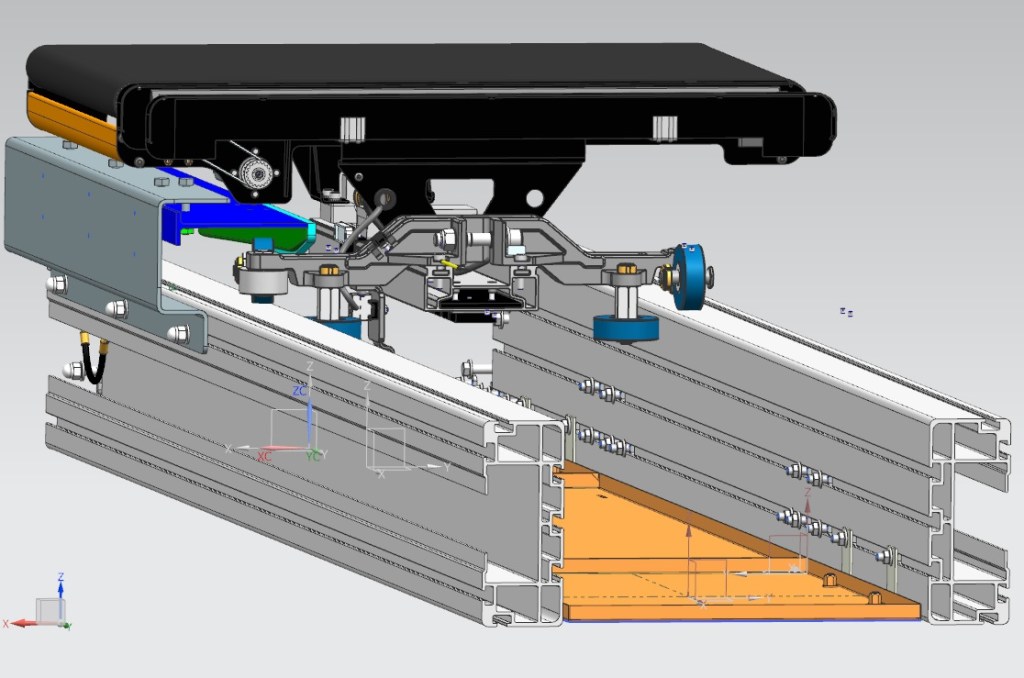

CASTER WHEEL ALIGNMENT SYSTEM FOR CONVEYOR SYSTEM | US11691816B2

This invention is a smart system designed to keep a loop of guided-wheels vehicles running smoothly by ensuring wheels are always correctly aligned. Think of it as a tool that “fixes” wheels that are facing the wrong way, engineering out eventual issues or breakages related to wrong installation or maintenance.

The system uses clever components like horizontal and vertical cams to gently guide misaligned wheels back into the proper position. If everything is already aligned, the system steps aside, letting vehicles pass through effortlessly. It’s particularly helpful during the installation of conveyor systems, saving time, preventing jams, and reducing wear and tear on equipment.

Ideal for circular sorters, in which the length of the loop can reach up to 3km and counting 4k vehicles, this innovative alignment system is like having an invisible mechanic on duty, ensuring everything keeps moving as it should, preventing issues related to human error. It can be even combined with sensors to take specific measurements.

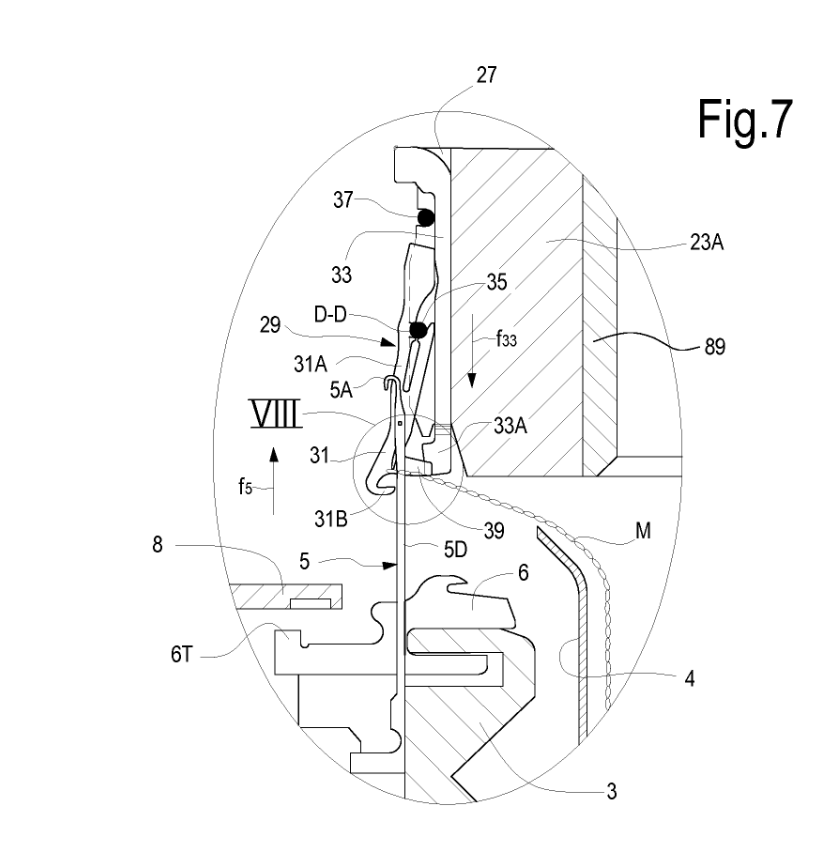

DEVICE AND METHOD FOR PICKING UP TUBULAR KNITTED ARTICLES FROM CIRCULAR KNITTING MACHINES | WO2017067801

This invention introduces an advanced pick-up device for efficiently handling tubular knitted articles, such as socks, directly from the needle cylinder of a circular knitting machine. A robotic arm manages and moves the picking device with precision, ensuring seamless operation and enhanced reliability. The picking device features a circular ring divided into two half-rings that can overturn onto each other around an axis perpendicular to the ring’s symmetry axis. Each half-ring houses a set of pick-up hooks equipped with radially extending spikes to grasp the fabric and abutment surfaces to align and position the open edge of the article.

This system addresses challenges in existing methods by reducing mechanical complexity and improving the precision of handling individual stitches, thus enhancing the linking or sewing process for the open edge. The robotic arm’s involvement minimizes errors associated with manual adjustments, ensuring consistent alignment and maintaining mechanical tolerances critical for high-quality output.

By simplifying operations, the device reduces production time and costs while maintaining the durability and ease of maintenance of the system. It outperforms traditional systems by integrating innovative features such as hook mobility, optimized fabric positioning, and robotic automation, making it ideal for industrial knitting applications where precision and efficiency are paramount.