EU Tech Program Manager – Amazon Robotics

Amazon Italia (LIN11) – Viale Monte Grappa 3/5, 20124 Milano (MI), Italy

From April 2020 – present

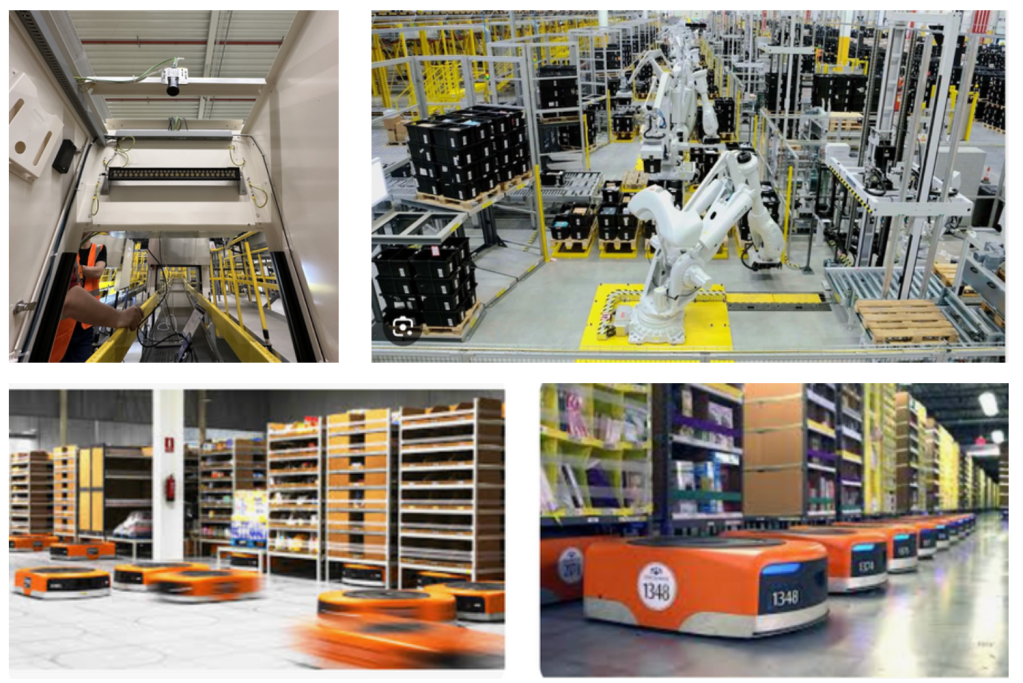

Amazon Robotics operates over 750,000 robots across 300+ fulfillment centers worldwide, cutting handling time by 50%. With $10B invested, it enhances efficiency, safety, and ergonomics, supporting Amazon’s rapid

logistics and expanding global operations.

I lead large scale programs (80MM+ USD, up to 9 PMs involved) across Amazon’s EU Fulfillment Network, driving the scalable integration of cutting-edge technical infrastructure solutions. I coordinate cross-functional teams and stakeholders to deliver high-impact, high-velocity deployments that enhance operational performance, enable automation at scale, and support Amazon’s long-term logistics innovation. My role focuses on business cases, program strategy, execution excellence, and continuous improvement across complex, tech-driven environments. Reporting to the EU portfolio senior manager.

- In 2026 I’m launching a 100M+ EUR Vulcan program (2026): Spearheaded business case and deployment strategy for breakthrough robotic manipulation technology presented by Amazon CEO. Secured executive buy-in and funding for enterprise-wide rollout of tactile sensing robotic arms, positioning Amazon at forefront of warehouse automation innovation.

- In 2025 I’ve Delivered 80M EUR autonomous robotics program (2025): Orchestrated end-to-end deployment of 9,000 AMRs across 31 fulfillment centers, increasing EU-UK network capacity by 10% and contributing 2% to global production capacity. Led team of 12 program managers and 100+ stakeholders, adapting strategy in real-time to shifting network priorities and achieving full deployment within budget and timeline constraints.

- In 2023-24 I led a 16M EUR budget program for the installation of vision systems in a beta stage (Developed by Amazon AI in Berlin) across 26 Amazon’s Fulfillment Centers, following it end to end from the creation of the business case and feasibility studies, to planning and execution, for a total of 14 months of duration. The program could count on 9 project managers for the project executions and it was proven to meet the expected break even of 1.2 yrs, despite the challenges we faced about the maturity of the tech and keeping up with the constant design changes. The program included the collaboration and the reporting to several teams and stakeholders, from the tech development teams to finance and local operations teams, which I handled through a constant risk tracking and weekly alignments on common strategies. Splitting the program in phases and conducting retrospectives for each one of them led to streamline operations and save 10% of the total program budget initially allocated.

- In 2022 I led a 15M EUR budget project in Zaragoza (Spain) for a duration of 10 months with 20 multidisciplinary people directly involved, installing 24 ABB robotic arms IRB series to automate a palletizing process in a new Amazon Building (ZAZ1) during its construction phase. The project was a novelty in Spain: It got UWED certified by TUV with minor snags and successfully completed on time within a 2% budget variance.

Product Optimization Leader, R&D – Dematic, KION GROUP

Dematic S.r.l., KION Group – Cernusco sul Naviglio (MI), Italy

From January 2018 to April 2022

Dematic, part of KION Group, employs over 11,000 people and operates in more than 35 countries, designing solutions for industries like retail, consumer goods, and manufacturing. It has completed 8,000+ installations globally, integrating robotics, automated storage, and software systems for optimized warehousing and logistics.

As functional manager I led a team of mechanical, and electronic engineers in the world wide ownership of circular sorters, designed and manufactured by the Italian division as a center of excellence. I was reporting directly to the Dematic’s Head of R&D.

Teamwork was carried out using the “Agile” principles, differentiating the activities in “Scrum” and “Kanban” according to the activity nature, and managing everything with the JIRA software.

The main activities consisted of:

- Improving the performances of circular sorters through the use of composite materials in the design phase (via Siemens NX11 and PLM management via Siemens Team Center and SAP)

- Root cause analysis directly in logistics plants based mainly in Europe and United States in case of design related issues

- Cost reduction through the use of highly automated production cycles. The cost of the axle of the SC3 carriers has been reduced by 50%.

- Development of a new contactless power supply technology with a view to minimizing downtime for maintenance: the most frequent maintenance interventions have gone from once every four months to once every two years.

- I personally handled the communication for the implementation of new features as well as the resolution of technical issues with the biggest customer, among the main ones: Amazon, DHL, Lockheed Martin, Lotte Logistics, across EU, NA and APAC.

- During my work in Dematic I filed a patent: “Caster wheel alignment system for conveyor system” which consists of a machine designed to facilitate assembly operations in the plant, guaranteeing a high-quality standard. This invention led to a project quality delivery KPI of the related topic form 98,50% to 99,97%.

- Development of the “double deck” SC3 design, in order to double the throughput performances of the circular sorter.

- Development of a sizing software for linear synchronous motors.

Technical Project Manager, R&D Mechatronics – Stäubli

Staubli Italia S.p.a. – Carate Brianza (MB), Italy

From April 2014 to December 2017

Stäubli is a global leader in industrial automation, specialized in robotics, connectors, and textile machinery. Founded in 1892, it has over 5,500 employees in 29 countries and three divisions. Stäubli’s robotics solutions, including its TX2 or the collaborative TX2 Touch and its controllers for robots CS9, serve sectors like automotive, healthcare, and electronics with high-precision, safe, and fast automation systems.

I was in charge of the “D4S” project, from the realization of the first prototypes to the commercialization of the pre-series, and the subsequent industrialization. I was reporting directly to the director of operations, and on a monthly basis to the CTO, since the “D4S” project was considered strategic for the organization to enter in the business of knitting and compete with the global leaders.

My activities, within a team of mechanical and software engineers, consisted of:

- Design using CAD CATIA V5 of a three-axis anthropomorphic robot, subsequently carrying out the complete kinematic simulation of the mechanism cycle using the Dassault Systemes Kinematics module

- Development of the control sensors system

- Development of the work cycle management software

- Collaborations with the key customers in Taiwan in testing the beta

- Industrialization activities following the pre-series

- During the development of the mechanical design, I filed the patent “Device and method for picking up tubular knitted articles from circular knitting machines” WO2017067801 : The patent consists of a method of transferring textile products between a circular knitting machine and an anthropomorphic robot. The patent includes the design of the gripping components of the robot. It has reduced the working cycle for more than a 20%, passing from 25 seconds to 19 seconds.